Every sound from an engine means something. Bothered? Have it checked and if your lifter does it, learn how to quiet a noisy lifter. Just keep on reading.

It feels very frustrating that after all the soundproofing I've done in my car, there is still a ticking sound that can be distinctly heard.

I had it checked and found that the noise source is a failing lifter. Got a similar problem? Before anything else, I would like to share some light about the so-called lifters.

The hydraulic valve lifter, a hydraulic tappet or simply lifter is a small cylindrical component of an engine connected to a rocket arm that pushes up to meet the valve.

It is the part of a car engine that uses oil pressure to adjust a plunger which in turn takes the clearance of the valve train.

This is also known as the valve lash. Lifters open and close the intake and exhaust valve.

The lifters are used in mass-produced vehicles where less maintenance is required. It is where the reduction of engine noise happens.

Too mechanical? Let's just say that the valve lifter is the finger-sized part of the engine responsible for making an engine run quietly.

Hydraulic lifters are more common in street automobiles. Lifter pump up is the major drawback of a hydraulic lifter that happens when it loses pressure at high engine RPM's reducing the lift of the valve.

There are other types of lifters such as the solid or mechanical lifter (common for racers) and the roller type (hydraulic lifter with roller).

Can noisy lifter cause damage?

However, like any other part of a car, hydraulic lifters are subject to wear. It is tiny but not invincible.

A faulty lifter produces annoying sound- a tap, tick and the like- that must be attended to diligently by car owners.

A worn or damaged lifter can click, tap or tick, Sometimes it starts as soon as you start your engine and last until it runs.

And the sound it’ll make and duration will tell you how bad of damage it has..

The tapping sound you initially hear and fade few seconds later is common and does not mean a serious problem.

It can only be an info for you that the engine is dirty already and warn you that that may decrease the optimum performance of the lifters.

But if the noise lasts longer than few second, you should be more attentive now because it may be more severe now. Other component might be in danger as well.

Fix it as soon as possible because delay can only worsen the situation.

What causes lifter to be noisy?

As mentioned, lifters significantly reduce engine noise, however, failure to do so is its signal that something is going west inside the hood. Detect the causes and repair will soon follow.

Most commonly, the possible cause of lifter ticks can be:

Overall, low oil pressure is fatal to valve lifters since it can indicate produce the clicking or tapping sound. Sometimes it shows up as a dash warning light or oil pressure gauge reading.

Detect and Repair a NOISY LIFTER

I always thought of my brother starting the car (about 15 minutes) before we depart is such a waste of gas and car battery.

But after learning that some unwanted noise-that exactly starts when the engine turns on- eventually dies on its own because of it, I stand corrected.

Actually, cars that haven't been active for a while do the noise thingy and if the problem is not severe, it will fade. He was right all along.

If the engine noise you hear is caused by a faulty lifter and you'll try to detect the true problem, you will need to isolate it then.

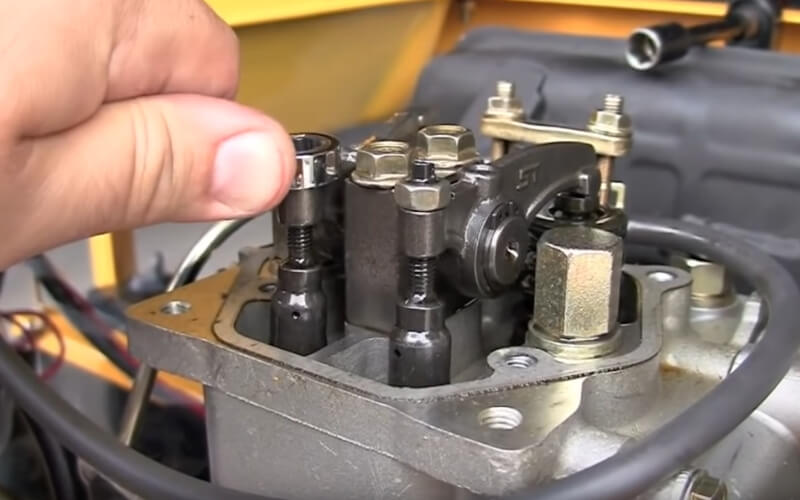

The simple use of a garden hose may fix the problem. The first thing to do is to remove the valve covers.

And as the engine runs, connect one end of the hose near the intake and exhaust valve.

Place the other end close to you so you can hear it clearly. You can pinpoint the problematic lifter.

Or if you want to play it safe and choose to detect a faulty lifter with an off engine, push down the rocker arms on the pushrod instead. It will be an effective indicator of a leaking filter if the rocker arms move too freely.

Once you are sure which part malfunctions, it is time for repair. Put your game face on!

1. Adjustment of Valves

Do you really have to adjust the self-adjusting lifter? Apparently, yes.

Hydraulic lifters are self-adjusting, but the other components are not. A noisy lifter might need some modification in the valve. It might be too tight or loose.

Position the lifters then try to twist the rocker arms. Loosen the locknut gradually while twisting the pushrod between fingers.

Found this helpful? Spread the word. Drive safely!

Tighten the nut while the rod twist until you reach 'zero lash' when the push rod no longer turns. Now the exciting part, turn the nut by half to full turn

Do the same to the rest of the valves you detected faulty. Check and try if your engine is back being quiet. A successful adjustment can bring back your car's optimum performance.

2. Change bent pushrods

Honestly, no one can judge you having fun with your car's accelerators. Sometimes you drive down a road that is smooth, wide, and empty, it is hard not to push hard that pedal for fun.

Yet, doing it over and over again can bend your pushrods. And the damage is not fun. You will endure noise if you let it be.

The one working with your lifter along with the camshaft and rocket arms is the pushrod. Bent pushrod may be because of a sticking hydraulic lifter or as mentioned, metal fatigue of hard footing.

Apparently, a bent pushrod can affect your car engine performance or worse, severely damage other connected parts.

Better call an auto repair technician in changing pushrods. But if you insist on doing it. You may.

Wiggle the pushrods to see how many are bent. Then remove the bent ones by pulling it up after you disconnected it from the rocket arms. Replace it with new ones before worse comes to worst.

3. Oil Change

Consider the engine oil to be your car's blood. It is what will keep it moving.

For it to properly run, the right amount and lubrication are needed. In fact, proper maintenance requires oil change regularly, maybe at least once or twice a year.

Can you use any oil? No. Too thick oils cannot easily be crept in the hydraulic lifter's tiny hole opening while oils that are too thin give insufficient lubrication for the engine to run.

A specialized oil must be used. Typically, such is slightly thicker than water.

First, check your oil level. The level must not be of course too low but not too high either or the oil pump will begin to suck in air or the rotating crankshaft and rods will drown.

For the sake of maintenance, completely drain the oil into your drain pan after allowing the engine to idle for 15 minutes.

You may use *Liqui Moly 2037 Pro-Line Engine Flush just to make sure that every last drop of old and clogged oil is out.

Once your oil filter is empty, you may refill it with new oil. Consult your engine specifications in choosing the right oil to be sure of the right product. It is not easy and free to drain and refill many times.

Liqui Moly 2037 Pro-Line Engine Flush is easy to use a detergent additive to effectively clean the interior engine before car's oil change. It removes residues and deposits by dissolving sludge and other contaminants.

4. Use Oil Additives

It did not occur to me that I'll personally be writing about engine oil additives until I was a victim myself by lifter noise.

It is an easy solution before going through the hurdles of buying and replacing components. This was first suggested to me by our kind mechanic.

Out of good heart, he thought that this will save me quite some bucks instead of immediately bringing my car to the shop.

The truth in cars is when oil flowing the engine becomes dirty, the lifter loses its performance and starts becoming noisy.

That's when oil additives join the picture. They are the liquid added to oils without affecting its viscosity.Oil additives can remove the accumulated dirt on your engine.

The Best Oil Additives for Noisy Lifters 2021

1. Liqui Moly 20004 Hydraulic Lifter Additive

2. Marvel Mystery Oil MM13R-6PK

3. BestLine Premium Synthetic Engine Treatment

4. TriboTEX Nano-Oil Additive Car Engine Treatment

5. Bar's Leaks Engine Treatment

5. Buy A New Lifter

When all is said and done, but still the noise that bothered you persists probably the last thing to consider doing is buying a new lifter.

Fortunately, it will not break the bank. It will cost you a few dollars, say $20, to buy a new one.

But a complete set containing all or most of the components that failed you will not exceed $300.

But of course, hiring a professional mechanic to do the job for you would be better although it will cost you a lot more.

The choice is yours to make because in a way, you could do it yourself. Use the one from performance tools when you remove the lifter from the entire engine.

If you have already made up your mind and risk doing it by yourself, better follow these steps.

- 1Prepare Top of Engine by removing the valve covers. It is locked by several bolts so undo all then remove the cover.

- 2Bring the first cylinder to the top center position. Remove the intake manifold bolts and observe the exact placement to make reassembly easier later on. Pull the intake and loosen up the manifold.

- 3Clean off the manifold from residues with a solvent. You may use a gasket scraper or a wire brush.

- 4Once the manifold is already clean, the rocker assembly bolts must be loosened to freely approach the pushrods. While on it, check the rods if there are any damaged ones. Using the suggested tool from performance tool or a strong magnet, lift out the hydraulic lifters

- 5Replace your old lifter now with the new hydraulic lifter you prepared. Make sure it can rotate without hindrance by 360 degrees. Push back the rods and rocket arm assembly.

- 6With the same placement from how you disconnected the parts, bring back the intake manifold or replace it with a new one. Place the valve covers again.

Frequently asked questions

As a bonus, let us try and answer some questions you have, shall we?

1. WHAT ARE BAD OR COLLAPSED LIFTER SYMPTOMS?

A bad lifter whether with damaged parts only or wholly collapsed gives a distinct sound to the driver.

A tapping sound will normally be produced and depending on oits duration & frequency, problems in lifter or adjacent parts can be determined.

2. CAN SYNTHETIC OIL QUIET NOISY LIFTERS?

Yes it can. Synthetic oils today can work as a double agent. It can be thin at first so the flow through the engine is smooth and turn thick when the engine runs steadily. It very well adjusts to engine’s operating temperature.

3. WILL THICKER OIL MAKE THE ENGINE QUIETER?

Not exactly because it depends on your car engine specification. Thicker or thinner oil can affect the performance of your engine.

The former gives better protection in engine but incur power loss. While the latter does not guarantee protection but allows smooth engine movement.

4. Does seafoam work for noisy lifters?

Yes, it does. Seafoam motor treatment works on any type of engine crankcase oil. It cleans and liquefies heavier oil deposits for a quiet noisy lifters.

A FINAL THOUGHT ON NOISY LIFTER

That's a wrap. Above are the possible causes and solutions for your noisy lifter.

If you will just take ample time to listen in your car cries, you will quickly identify the source of what makes it whine.

You may choose to spend on professional help and relax while everything is being taken care of. Or unleash the risk-taker in you.

Inspect before jumping into the conclusion that something or someone may be haunting you. Soundproof your car first and if the problem continues, open up your hood, your lifter may be at fault.

Don't worry, we have your back because after reading the possible solutions on how to quiet a noisy lifter, you are well informed.

Anyway, at all costs, approach everything scientifically. As the saying goes, ‘Everything Has A Reason’. And that annoying sound has too.

Jessica is a Acoustical Engineer, currently based in the San Francisco Bay Area in California. After graduating from her degree in Master of Engineering degree in Acoustics from Solent University in 2014, Jessica worked for a few companies before She will be blogging about her past and current experiences in the studio and sharing her journey as she pursues her career goals. She enjoy the balance of work inside and out of the office, solving practical problems on a daily basis as every project is different and requires a different solution, the variety of work (sound insulation testing, background noise survey, mechanical plant commissioning, external plant assessment, plant room breakout assessments) and the mix of independent and team work.

the has a noise on the top head on number 1 and is not firing on number 1 again has amisfiring but plugs are new